Exploring the Functionality and Applications of Control Valves in Industrial Processes

The Role of Control Valves in Industrial Automation

- Introduction: Control valves play a crucial role in industrial automation by regulating the flow, pressure, and temperature of fluids in various processes. These valves are essential for achieving precise control and ensuring the efficient operation of different systems. In this section, we will delve into the significance of control valves and their contributions to industrial automation.

- Importance of Control Valves: Control valves serve as critical components in industrial processes where maintaining the desired setpoints is vital. These valves ensure that the flow of liquids or gases is controlled within specific parameters, preventing equipment damage and ensuring optimal performance. By regulating fluid flow, pressure, and temperature, control valves enable businesses to achieve increased productivity, energy efficiency, and product quality.

Types of Control Valves and Their Operating Principles

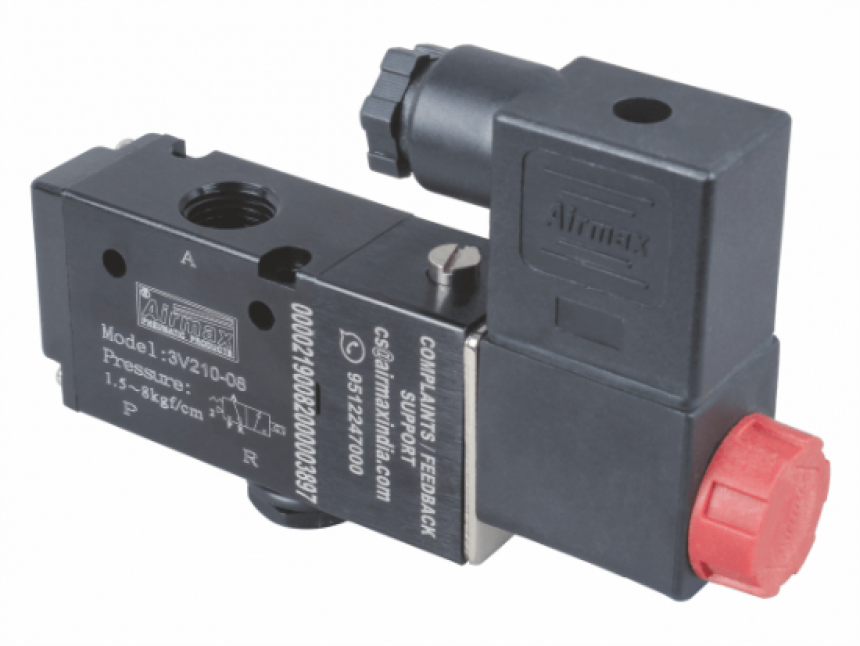

- Control Valve Classification: Control valves come in various types, each designed to meet specific requirements and applications. Some commonly used control valves include globe valves, butterfly valves, ball valves, and diaphragm valves. These valves operate based on different principles, such as throttling, on-off control, and pressure regulation.

- Throttling Valves: Throttling valves, like globe valves, are commonly used for precise control of fluid flow. They operate by adjusting the opening of the valve plug or disc to regulate the flow rate. This type of valve provides excellent control accuracy but may result in energy losses due to pressure drop.

- On-Off Valves: On-off valves, including ball valves and butterfly valves, provide a binary control function by allowing or blocking fluid flow completely. These valves are suitable for applications where simple start-stop control is required. However, they do not offer the same level of precision as throttling valves.

- Pressure-Regulating Valves: Pressure-regulating valves, such as relief valves and pressure-reducing valves, maintain a specific pressure level within a system. These valves are essential for preventing excessive pressure buildup, protecting equipment, and ensuring operational safety.

Key Components and Working Mechanisms of Control Valves

- Components of Control Valves: Control valves consist of several essential components that work together to regulate fluid flow. These components include the valve body, actuator, positioner, and valve trim. The valve body provides the passage for fluid flow, while the actuator controls the valve's opening and closing. The positioner ensures accurate valve positioning, and the valve trim, including the plug, disc, or ball, modulates the fluid flow.

- Working Mechanisms: The working mechanisms of control valves involve the interaction between the actuator and the valve trim. Depending on the type of control valve, the actuator can be pneumatic, hydraulic, or electric. When a control signal is received, the actuator moves the valve trim, adjusting the flow area and thus regulating the fluid flow, pressure, or temperature.

Applications of Control Valves in Different Industries

- Oil and Gas Industry: In the oil and gas industry, control valves are used extensively for applications such as flow control in pipelines, pressure regulation in refineries, and level control in storage tanks. These valves ensure safe and efficient operation, prevent leaks, and enable accurate measurement and control of various parameters.

- Chemical Industry: Control valves are crucial in the chemical industry, where precise control of chemical processes is essential. They are used for controlling flow rates, mixing and reacting chemicals, and maintaining optimal temperatures and pressures in reactors and distillation columns. Control valves play a vital role in ensuring product quality, reducing waste, and improving overall process efficiency.

- Water Treatment and Utilities: In the water treatment and utility sector, control valves are employed for controlling water flow, pressure, and level in treatment plants, pumping stations, and distribution networks. These valves help maintain consistent water quality, optimize energy consumption, and ensure a reliable supply of clean water to consumers.

- Power Generation: Control valves are integral to power generation processes, including steam turbines, boilers, and cooling systems. They regulate steam flow, control fuel, and air supply, and manage condenser pressure to ensure efficient power generation. Control valves help optimize energy production, enhance plant safety, and minimize environmental impacts.

- Food and Beverage Industry: In the food and beverage industry, control valves are used for precise control of ingredients, temperature, and pressure in various processing stages. They play a critical role in maintaining product consistency, ensuring food safety, and optimizing production efficiency.

- HVAC and Building Automation: Control valves are widely employed in heating, ventilation, and air conditioning (HVAC) systems for temperature and flow control. They help regulate heating and cooling fluids, ensuring comfortable indoor environments while minimizing energy consumption.

Importance of Proper Maintenance and Troubleshooting of Control Valves

- Importance of Maintenance: Proper maintenance of control valves is crucial for ensuring their reliable performance and longevity. Regular inspections, cleaning, and lubrication of valve components help prevent corrosion, leakage, and malfunctioning. Additionally, calibration of control valve instruments and actuators ensures accurate control and adherence to setpoints.

- Troubleshooting: Control valves may encounter issues such as excessive leakage, improper response, or erratic behavior. Troubleshooting these problems requires a systematic approach, including identifying the root cause, inspecting valve components, and adjusting or replacing faulty parts. Timely troubleshooting and resolution of control valve issues help prevent process disruptions, equipment damage, and potential safety hazards.

Conclusion:

Control valves are indispensable components in industrial processes, enabling precise control of fluid flow, pressure, and temperature. They find applications across various industries, including oil and gas, chemical, water treatment, power generation, food and beverage, and HVAC. Understanding the different types, components, and working mechanisms of control valves is crucial for their effective utilization. Proper maintenance and troubleshooting of control valves ensure their reliable performance, maximize operational efficiency, and contribute to the overall success of industrial automation processes.

Need help in growing your business? If you care for your business and want to see it at the top like them, you can contact Grow Media Digital. Grow Media Digital is a one-stop solution for every digital need. For More Details, Visit Our Official Website: https://www.growmedia.digital/